The way your business manages logistics can make or break your growth. Customers now expect fast, affordable, and reliable delivery, plus full visibility from checkout to doorstep. Meeting those expectations while keeping costs under control isn’t easy — and that’s where logistics partners step in.

For many businesses, the first step is working with a Third-Party Logistics provider (3PL) to handle storage, fulfilment, and shipping. But as operations become more complex, or if a requirement is predominantly transport, some brands add a Fourth-Party Logistics provider (4PL) to manage the bigger picture — coordinating multiple providers, carriers, and freight partners into one smooth operation.

This guide explores the differences between 3PLs and 4PLs, how they complement each other, and when adding a 4PL layer could be the key to scaling your eCommerce business.

The Evolution of eCommerce Logistics

As your business grows, logistics naturally become more complex. The right approach often depends on where you are in your journey:

- Early Stage → Fulfilling orders in-house works while volumes are low.

- Scaling Up → Partnering with a 3PL to manage day-to-day fulfilment efficiently.

- Managing Complexity → Introducing a 4PL to unify multiple providers, warehouses, and freight partners under one central strategy.

What is a 3PL?

A Third-Party Logistics provider (3PL) specialises in operational fulfilment — handling the physical side of getting products from your storage facility to your customer’s doorstep.

Typical services include:

- Inventory storage and warehouse management

- Picking, packing, and labelling orders

- Booking and managing couriers

- Returns processing and restocking

- Providing dashboards and order tracking for better visibility

The benefit of a 3PL is efficiency without losing control. You decide on customer-facing elements like packaging, carrier preferences, and delivery speeds while your 3PL executes the operational tasks.

For small and mid-sized eCommerce brands, a 3PL is often the first step towards scalable fulfilment.

What is a 4PL?

A Fourth-Party Logistics provider (4PL) is a full logistics management solution, taking responsibility for the design, coordination, and optimisation of the entire supply chain. Unlike a 3PL, which delivers on specific services, a 4PL oversees every element – from inbound freight and warehousing to carrier selection and cross-border movements – ensuring the whole operation runs as one seamless system.

Key strengths of a 4PL include:

· Strategic oversight & accountability

A 4PL doesn’t just execute tasks – it manages performance across the whole supply chain, ensuring cost efficiency, reliability, and service quality.

· Scalability & flexibility

By combining access to multiple partners and networks, a 4PL can adapt to fluctuations in demand – whether managing a single load or overseeing end-to-end logistics at scale.

· Optimised cost, speed, and reliability

With the freedom to select the best carriers, modes, and routes, a 4PL balances cost, capacity, and service levels to deliver the right outcome for each movement.

· End-to-end visibility

A 4PL provides real-time visibility across the supply chain, giving businesses the data they need to make informed decisions and improve performance.

· Resilience & risk management

By leveraging broad networks and expertise, a 4PL can mitigate disruption – ensuring continuity even during peak seasons, cross-border challenges, or capacity shortages.

Why this matters: Cross-border eCommerce is substantial and growing. In the UK, 36% of online shoppers buy from retailers in other countries, which shows why having a 4PL to manage cross-border operations is becoming increasingly important.

Key Differences Between 3PL and 4PL

While both 3PLs and 4PLs support eCommerce fulfilment, they offer different levels of control, scope, and visibility.

Service Scope

– 3PLs focus on execution: storage, picking, packing, and delivery.

– 4PLs focus on management: coordinating multiple providers and optimising end-to-end supply chains.

Level of Control

– With a 3PL, businesses retain more control over packaging, courier selection, and the customer experience.

– With a 4PL, some control shifts towards standardisation for efficiency across the network.

Technology Utilisation

– 3PLs typically provide dashboards, order tracking, and stock visibility.

– 4PLs use advanced platforms to integrate data from multiple partners for real-time insights.

Examples of a 3PL and a 4PL

To better understand how 3PLs and 4PLs differ in practice, here are two examples of providers and what they offer:

Example of a 3PL — PackPro Fulfilment

PackPro Fulfilment is a UK 3PL provider that works with eCommerce brands of all sizes, including many based outside the UK. Once your stock arrives at their facility, PackPro handles:

- Storage of your products

- Picking, packing, and labelling customer orders

- Fast shipping across the UK and Europe

- Integration with your existing sales channels, including Shopify, Amazon, and other marketplaces

PackPro focuses on making UK and European fulfilment simple, cost-effective, and efficient, helping brands deliver faster while avoiding the overhead of setting up their own infrastructure.

Example of a 4PL — X2 UK

X2 UK is a fourth-party logistics provider that takes a broader, more strategic role. Instead of just handling order fulfilment, they manage your entire supply chain by:

- Coordinating multiple 3PLs and fulfilment centres

- Managing inbound freight from suppliers or ports

- Handling cross-border shipping and customs clearance

- Optimising carrier selection to reduce costs and improve delivery times

- Providing full visibility across your logistics network

X2 UK is ideal for brands managing international complexity and needing one point of contact to oversee everything from supplier freight to final-mile delivery.

How a 4PL and 3PL Work Together

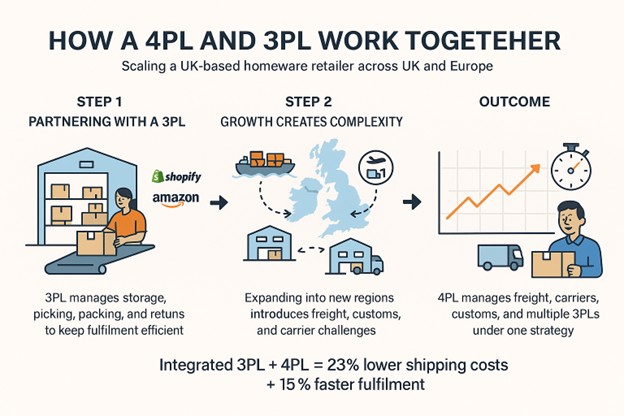

Consider a UK-based homeware retailer scaling across the UK and Europe.

Step 1 — Partnering with a 3PL

The retailer partners with a specialist 3PL to handle warehousing, picking, packing, and returns. Orders flow seamlessly through integrations, and the 3PL keeps fulfilment accurate and efficient.

Step 2 — Growth Creates Complexity

The retailer starts importing stock from suppliers in Asia and opens a second fulfilment site in mainland Europe. Managing freight, customs clearance, multiple carriers, and stock across two warehouses becomes challenging.

Step 3 — Adding a 4PL Layer

Instead of replacing their 3PL, the retailer partners with a 4PL. The 4PL arranges inbound freight from suppliers, books deliveries into the 3PL’s warehouse, oversees trunking between fulfilment centres, and negotiates competitive carrier contracts across regions.

Outcome

With the 4PL managing the logistics strategy and the 3PL focused on fulfilment execution, the retailer achieves faster lead times, better cost control, and improved visibility — without disrupting their existing operations. In fact, retailers using an integrated 3PL + 4PL model see an average 23% reduction in shipping costs and 15% faster order fulfilment times.

Conclusion

For growing eCommerce brands, logistics aren’t just about getting products from A to B — they’re a strategic driver of growth. A 3PL gives you efficient, accurate fulfilment, while a 4PL adds the oversight and coordination needed to manage increasingly complex supply chains.

X2 UK

If you’re ready to centralise your operations, simplify freight management, and gain full supply chain visibility, a trusted 4PL partner like X2 UK can help connect the dots. From managing inbound freight and coordinating carriers to optimising cross-border logistics and providing real-time visibility, X2 UK delivers the control and efficiency you need to scale confidently. With a single point of contact overseeing your supply chain, you can reduce complexity, improve delivery performance, and focus on growing your business.